| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Gofine

Model Number : GF-1240

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : $15800-18000

Payment Terms : L/C,T/T,Western Union,MoneyGram

Supply Ability : 25 Sets/Month

Delivery Time : 25 Sets/Month

Packaging Details : plywood case

Granulation Ratio : more than 95%

Granular Size : 2-6mm

Materials : normal steel or SS

Rotary Speed : 11r/min

Applications : Fertilizer granule granulation

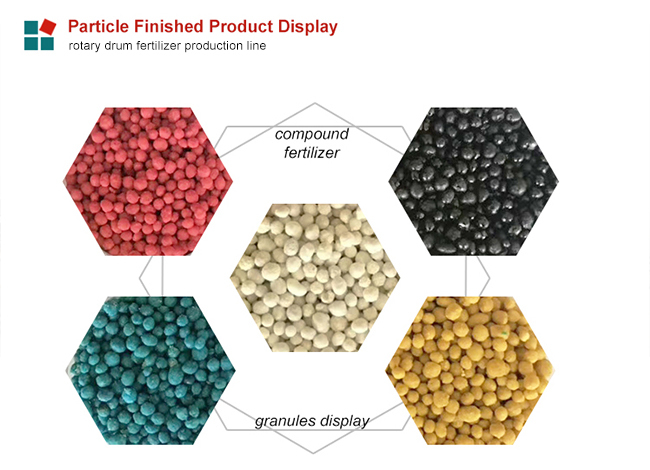

Granules Shapes : Ball Shape

Speed : 17r/min

Raw Materials : Urea, DAP, MAP, SSP, TSP, MOP, KCl, etc.

Model : Various models available

Temperature : room temperature

Volatge : Customized

Production Description:

Achieve optimal soil health and maximize crop yields with our Integrated Organic/Inorganic Fertilizer Manufacturing Equipment. This NPK Fertilizer Production Plant provides a comprehensive solution for producing balanced fertilizers that combine the benefits of both organic matter and essential inorganic nutrients. Our customizable systems allow you to create high-quality fertilizers tailored to specific crop needs and soil conditions, promoting sustainable agricultural practices and reducing reliance on purely synthetic inputs.

Features:

Integrated Production: Combines organic and inorganic fertilizer production processes in a single, streamlined system, maximizing efficiency and minimizing handling.

Versatile Material Handling: Handles a wide range of raw materials, including livestock manure, agricultural residues, compost, urea, ammonium phosphate, potassium chloride, and other organic and inorganic sources.

Customizable Formulations: Produces NPK compound fertilizers with customizable nutrient ratios, as well as organic-inorganic blends tailored to specific crop requirements.

Automated Batching & Mixing: Ensures precise proportioning of organic and inorganic materials for consistent nutrient content and product quality.

Efficient Granulation: Employs advanced granulation technologies (rotary drum, disc, extrusion) to create uniform, high-strength granules for easy handling and application.

Optional Anaerobic Fermentation: Integration of anaerobic fermentation technology stabilizes organic waste, enriches the nutrient profile, and generates biogas as a renewable energy source.

Integrated Drying & Cooling: Optimizes moisture content and granule stability for improved product quality and extended shelf life.

Screening & Coating (Optional): Separates granules by size for consistent product quality and applies coatings to prevent caking and control nutrient release.

Automated Packaging Systems: Provides efficient and accurate weighing and bagging of finished fertilizer products.

Odor & Dust Control: Incorporates environmental protection measures to minimize dust and gas emissions.

Applications:

Balanced Fertilizer Production: Manufacturing of fertilizers that combine the slow-release benefits of organic matter with the readily available nutrients of inorganic fertilizers.

NPK Fertilizer Production: Production of granular NPK fertilizers with various nutrient ratios to meet the specific needs of different crops.

Bio-Organic Fertilizer Production: Combining organic materials with beneficial microorganisms to create enhanced bio-organic fertilizers.

Soil Amendment: Producing fertilizers that improve soil structure, water retention, and nutrient availability.

Working Process:

Raw Material Preparation: Organic materials (manure, compost) undergo pre-treatment such as fermentation and crushing. Inorganic materials (urea, ammonium phosphate, potassium chloride) are prepared for mixing.

Automated Batching & Mixing: Organic and inorganic materials are automatically batched and precisely mixed according to the desired fertilizer formulation.

Granulation: The mixed materials are granulated using a suitable method (rotary drum, disc, extrusion) to form granules. Wet granulation may involve spraying a liquid binder.

Drying: The wet granules are dried at low temperatures (around 90°C) to preserve heat-sensitive components. Waste heat can be used for drying.

Cooling: The dried granules are cooled to stabilize them and prepare them for screening and coating.

Screening: Granules are screened to separate them by size, ensuring a uniform product. Oversized and undersized particles are typically recycled.

Coating (Optional): Granules may be coated to improve handling characteristics, control nutrient release, or enhance their appearance.

Packaging: The finished fertilizer granules are automatically weighed and packaged into bags for storage and distribution.

Contact us today to discuss your fertilizer production needs and learn how our Integrated Organic/Inorganic Fertilizer Manufacturing Equipment can help you achieve your business goals and promote sustainable agriculture.

Product Details

|

|

NPK Fertilizer Production Plant for Organic Inorganic Granules Images |