| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Gofine

Model Number : 30 m³

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : $12000~15000

Payment Terms : L/C,T/T,Western Union,MoneyGram

Supply Ability : 25 Sets/Month

Delivery Time : 1-3 Sets/15days

Packaging Details : plywood case

Fertilizer Efficiency : High

Power Source : Electric

Control Method : Fully Automatic PLC + Touch Screen

Processing Cycle : 10H

Volume : 30 m3

Warranty Period : 1 Year

Organic Matter : high

Applications : Composting Plants, Food Wast, etc.

Features : Fully Automatic

Application : Organic Fertilizer Production

Product Description:

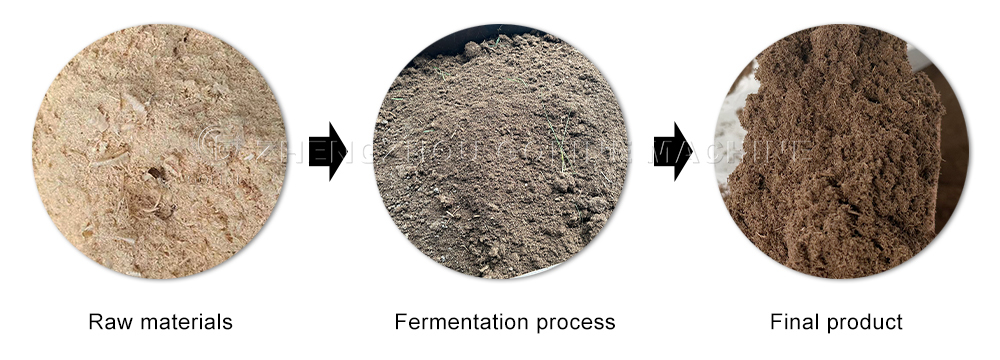

As a leading Organic Fertilizer Composting Aerobic Fermentation Fertilizer Equipment Manufacturer, we provide innovative and reliable solutions for transforming organic waste into high-quality organic fertilizer. Our systems utilize efficient aerobic fermentation to accelerate composting, reduce odors, and produce a nutrient-rich soil amendment that promotes sustainable agriculture and improves soil health.

Features:

Efficient Aerobic Fermentation: Our equipment utilizes aerobic microorganisms to rapidly break down organic matter in a controlled environment with sufficient oxygen. This process ensures efficient composting, minimizes odors, and maximizes nutrient retention.

High-Temperature Composting (Optional): Some models operate in a high-temperature range (60-80°C or higher), effectively eliminating pathogens, parasites, weed seeds, and other harmful substances.

Versatile Waste Processing: Handles a wide range of organic waste materials, including livestock manure (cow, chicken, pig), agricultural residues (straw, stalks), food scraps, municipal solid waste, and more.

Customizable Solutions: We offer a variety of equipment types and configurations to suit different composting methods and production scales, including compost turners, fermentation tanks, and complete production lines.

Automated Control System: Equipped with a smart control system that monitors and regulates key parameters such as temperature, moisture, oxygen levels, and pH for optimal composting conditions.

Odor Control System: Integrated deodorization systems minimize unpleasant odors and ensure compliance with environmental regulations. These systems may use biological deodorization or other advanced technologies.

Durable Construction: Built with high-quality, corrosion-resistant materials for long-lasting performance and reliability.

Complete Production Line Integration: We offer complete fertilizer production lines that integrate feeding systems, crushers, mixers, screeners, granulators, dryers, coolers, and packaging machines for a seamless and efficient process.

Applications:

Organic Fertilizer Production: Converts organic waste into nutrient-rich compost for use as a natural and effective fertilizer, improving soil health and increasing crop yields.

Waste Management: Reduces the volume of organic waste sent to landfills, minimizing environmental pollution and promoting sustainable waste disposal.

Sustainable Agriculture: Supports sustainable farming practices by providing a natural and renewable source of fertilizer, reducing the need for chemical fertilizers.

Livestock Farms: Ideal for livestock farms of all sizes, providing an efficient solution for manure management and fertilizer production.

Municipal Waste Treatment: Suitable for processing organic waste in municipal composting facilities.

Horticulture and Landscaping: Produces compost for use in landscaping and horticultural applications.

Working Process (Example using a Compost Turner):

Waste Collection & Sorting: Collect organic waste materials and sort to remove any non-organic contaminants.

Material Preparation: Mix organic waste with other materials (e.g., straw, wood chips) to adjust the carbon-to-nitrogen ratio (C:N) and optimize composting.

Windrow Formation: Arrange the mixed materials into long piles called windrows.

Composting: A compost turner regularly turns the windrows, aerating the pile and promoting microbial activity.

Monitoring & Adjustment: Monitor the temperature, moisture, and oxygen levels within the windrow and adjust turning frequency as needed to maintain optimal composting conditions.

Curing (Optional): After composting, the material may be cured to further stabilize and enhance its quality.

Further Processing (Optional): The compost can be further processed through crushing, screening, and packaging to create a commercial product.

Why Choose Us?

Experienced Manufacturer: We have years of experience in designing and manufacturing fertilizer equipment.

Customized Solutions: We offer tailored solutions to meet your specific needs and requirements.

Quality and Reliability: Our equipment is built with high-quality materials and components for long-lasting performance.

Comprehensive Support: We provide comprehensive support, including installation, training, and after-sales service.

Contact us today to learn more about our Organic Fertilizer Composting Aerobic Fermentation Fertilizer Equipment and how we can help you achieve sustainable waste management and organic fertilizer production goals.

Product Details

|

|

Fully Automatic PLC Organic Fertilizer Composting Machine 30 m3 Images |